191 Ton x 166″ Amada HFE-M2-1704 Press Brake

8-Axes CNC Control and Backgauge

Manufactured in 2012

Request QuoteAmada HFE M2 series

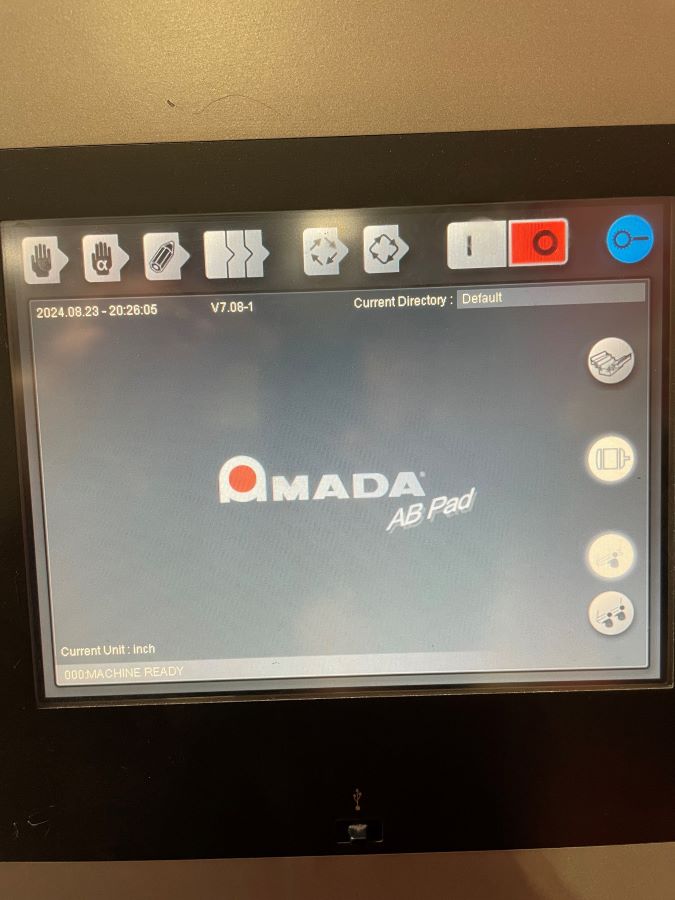

Built on the solid foundation of the HFE series, Amada’s HFE M2 press brake models include additional production-enhancing features and an innovative touch-screen AB PAD interface. Overall design improvements result in an eco-friendly series that provide maximum performance and ease of use. Equipped with an energy saving drive — the inverter on the HFE M2 series reflects Amada’s ongoing

commitment to environmental protection. The new drive system uses a frequency inverter that controls the motor pump and ensures efficiency by operating only when necessary. The system continually monitors and self-regulates bending requirements — this translates to using 20% less energy, a significant reduction

in maintenance requirements, less oil consumption, lower noise levels, and an increase in reliability.

Press Brake Specifications

Maximum Tonnage: 191 US Tons

Minimum Tonnage: 23.6 US Tons

Working Length: 166”

Table Width: 7.09”

Working Height: 37.8”

Open Height 18.5”

Stroke Length: 7.87”

Throat Depth: 16.5”

Distance between Frames: 148”

Oil Capacity: 62.1”

Approach Speeds

Maximum Approach Speed: 3.94 inches per second

Maximum Bending Speed: 0.39 inches per second

Maximum Return Speed: 3.94 inches per second

Machine Dimensions

Total Length: 217.7”

Total Width: 103.3”

Total Height: 113.8”

Total Weight: 30,645 lbs

Power consumption: 18 kVA

Equipped with

Amada AB Pad control and this machine is the 8-Axes version

CNC backgauge axes include X1, X2, R, Z1, Z2 and “L-shift”

Lower beam using Amada’s patented deflection system for accurate parallel bending